Application of Shenzhen JEET industrial endoscope in Aeroengine

Application of Shenzhen JEET industrial endoscope in Aeroengine

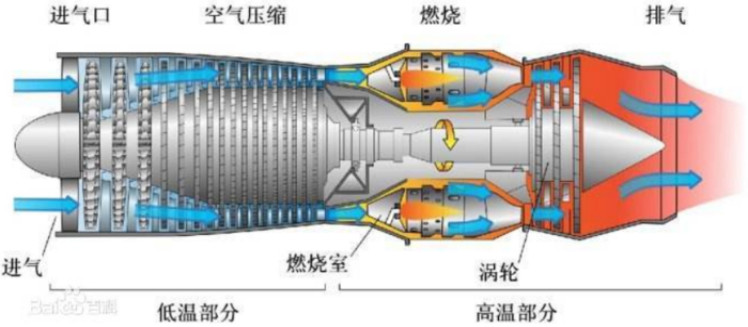

Aeroengine is the main source of aircraft power, which directly affects the safety of aircraft. The working conditions of the aero-engine are very harsh, usually, the working temperature is above 1700 ℃. The rotation speed of 3000-5000 revolutions per minute is a great test for the quality of the hardware of the aircraft, resulting in a centrifugal force with a destructive level. During the use of an aero-engine, the core parts such as the axial-flow compressor, combustion chamber, and turbine blade are the most frequent faults, which is a potential threat to the engine. At the same time, the fault often occurs inside the engine, and it is difficult to find the damaged part from the appearance. If all the engines are disassembled for inspection, it will cost a lot of labor and time, and the work efficiency will be sharply reduced.

Selecting Shenzhen JEET THX Series megapixel high-definition industrial endoscope , the detection technology can present the defects at the detection points on the IPS high-definition full view screen with smooth, clear, high-resolution, and complete color images, and carry out the intelligent image system analysis on the observation images to visually judge the detection situation. At the same time, it can be transmitted to other devices through HDMI image transmission or WiFi and can be used for photographing and video recording at any time. It is fast and convenient to use. When using the industrial endoscope, the size, length, and complex path of the inspected aperture are considered according to the actual detection situation, the flexible hose endoscope is selected, and the rigid tube endoscope is selected for the simple path. Shenzhen JEET is committed to providing customers with professional endoscopic video detection solutions, and each series of products can cope with different detection environments.

How about Shenzhen JEET Technology Co., Ltd?

JEET Technology has its production workshop and professional technical team and has also introduced the world's advanced production equipment, dust-free workshop, and production line to ensure the quality and technology of videoscope products.

JEET endoscope manufacturer has rich experience and superior industrial endoscopes, which can better communicate with customers. If you want to purchase industrial endoscopes, choose JEET Technology, I believe you will get a satisfactory answer here.

What is the goal of JEET Technology?

As we all know, it is not easy for industrial endoscope manufacturers to obtain good quality. After all, industrial endoscopes are relatively mature in foreign countries, with more functions, and can be matched with different products. In addition, there are many manufacturing processes of the industrial borescope, which require the cooperation of multiple departments. As a manufacturer, we need to overcome difficulties. So, the goal of JEET Technology is to make the best domestic industrial endoscope.